Tire Tank

Overview

Large rubber tires from heavy earth-moving, construction, or agricultural machinery can be modified into reliable livestock watering tanks that are durable and relatively inexpensive. Tires utilized for this purpose should be of sufficient depth and diameter when laid on their sides to have the desired water storage capacity. Also important is the ability to remove all or part of the upper sidewall of the tire to allow livestock access to the water. Tire tanks can be used in most locations suitable for any open-topped tank, and are relatively freeze-resistant (but not freeze-proof) during the winter.

Advantages

- Simple and relatively inexpensive.

- Available in a wide variety of sizes.

- Durable and non-breakable; no sharp edges to injure livestock.

- Can be used with both pressurized and gravity-flow water systems.

- Can use larger dimension pipeline and plumbing for faster refill rates.

Limitations

- Larger tires are heavy to handle during installation.

- Larger tires and/or multiple tires may be needed for large herds.

- Removing part or all of one sidewall can be difficult.

Design Considerations

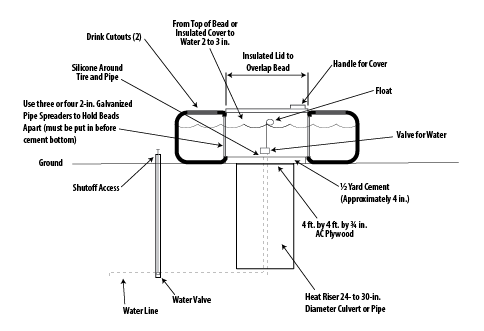

Most tire tanks cost a few hundred dollars. Used tires are often donated by companies using heavy equipment. Tire size should be selected based on the size of the herd to be watered. Tires used for tanks are typically 4 to 13 feet in diameter. When the tire tread is too wide (side of the tank is too high when the tire is lying on its side), the tire can be partially buried to reduce the height, which will also increase freeze protection. If the water depth in the tire will be greater than 25 inches, the producer may be advised to select a narrower tire. Minimum depth is often 12 to 15 inches in order to have adequate depth for the float system to work.

The tire sidewall is cut away either partially or entirely on what will be the top side of the tank for livestock’s access to water. A heavy-duty reciprocating saw works well in most cases. Cutting holes rather than removing the entire sidewall will improve freeze resistance but limit the number of livestock that can drink at one time. Tires with the sidewall already removed are available from several suppliers.

Tire tanks are usually supplied with water by an underground pipeline from the water source Water can gravity flow from springs or ponds, or from pressurized sources such as wells or rural water supplies. A float valve is usually installed to regulate water flow into the tank. The brass nipple installed through the concrete bottom of the tank should be located so that the float is near the center of the tank. The length of the float arm may require installing the nipple closer to the side of the tank but still a few inches away from the tire bead. Water supply lines should be a minimum diameter of one inch for pressurized water systems and two inches for gravity-flow systems. Drain and/or overflow lines should be planned to carry away excess water or prevent freezing and are also helpful when cleaning the tank.

The tank bottom is sealed with concrete, bentonite, or other heavy clay to prevent leakage. Another sealing option is to use a heavy metal or plastic plate screwed to the tire.

A layer of geotextile fabric laid on the soil under the tire before tank installation can be covered with a 6-8 inch layer of coarse gravel around the tank to create a protected heavy-use area that provides a durable, hardened surface that reduces muddy conditions. Installing a deck of used railroad ties adjacent to the tank gives small calves access to water when the tank sides are high. A protective railing over or around the tank keeps livestock from wading or being inadvertently pushed into the tank and helps protect the piping and floats in the tank.