Hardened Surface

Overview

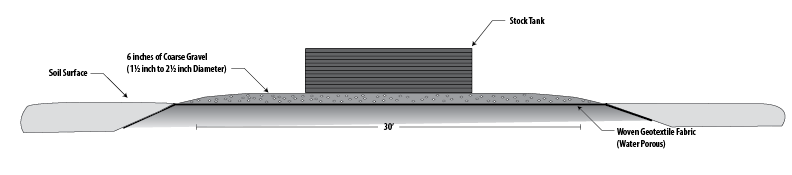

To avoid mud around permanent tank locations, the space around the tank should be protected by a hard surface (concrete) or hardened surface (geotextile-gravel surfacing). A larger area can be protected by combining both a concrete pad and a surrounding hardened surface.

Concrete is an excellent long-life surfacing material. Soil cement or fly ash can be a less expensive option for providing a durable hard surface, but with a shorter life than concrete.

Geotextile covered with layers of gravel provides drainage through the surface as all materials are porous. Two-inch diameter gravel provides a firm base but is uncomfortable enough that cattle won’t linger by the water and destroy nearby vegetation.

Movable tanks that are frequently relocated to avoid the development of a high-use area with damaged vegetation and mud may not need a hardened surface.

Hardened surfaces can also be used in other high-use pasture areas such as winter feeding sites to avoid mud buildup.

Advantages

- Can be used around a wide variety of livestock waterers, both existing and new.

- Water drains away from the waterer rather than pooling at the base.

- Can be used for winter feeding sites as well as around waterers.

- Allows easier removal of any manure buildup.

- Improves runoff water quality.

- Can combine concrete and hardened surface to protect a larger area at a more moderate cost.

- Improves livestock performance by avoiding losses attributable to mud.

Limitations

- Must be periodically maintained with additional gravel.

- Some site preparation may be necessary where ground is not level.

Design Considerations

Locate hardened pads on firm soil, first scraping to remove all vegetation, roots, and rocks. Grade the site to slope ¾ to 1 inch per foot away from the waterer. The recommended minimum width of a hardened surface around a waterer is ten feet.

Unroll the geotextile directly on the soil where it will be installed. Overlap strips of geotextile by at least 18 inches. Remove wrinkles but do not stretch the fabric. Cover the geotextile with rock within 48 hours of installation to avoid textile damage due to sunlight.

Cover the geotextile with a 4-6 inch layer of coarse gravel and then add a 2-3 inch layer of finer aggregate (not as fine as sand). Do not drive directly on the geotextile during rock installation.

When combining a hardened surface with a concrete pad, the hardened surface should extend at least two feet under the edge of the concrete.

Maintain the hardened surface by periodically removing manure and feed and reapplying fine aggregate before the lower layer of rock is exposed.