Insulated Waterer

Overview

Keeping water ice free is a challenge for livestock producers in colder climates. Heating elements or gas burners installed in tanks to prevent freezing are often problematic. Waterers designed from molded plastic with high insulation values* provide liquid water for livestock during the winter in the central United States without the use of auxiliary heating.

*(R-factor – resistance to heat flow)

Advantages

- No need for supplemental heat to prevent freeze-up.

- Available from local farm supply stores.

- Availability of parts is good.

- Livestock learn to use them easily.

- Do not rust.

- Use UV-resistant molded plastic to reduce solar degradation.

Limitations

- Require frequent checking during inclement weather.

- Can be damaged if allowed to freeze repeatedly during periods without livestock use. Livestock herd winter water requirements should be matched to waterer size to ensure three or more complete water changes/day in the waterer.

- Generally, requires a concrete pad base.

Design Considerations

Insulated waterers rely on warm recharge water from the pipeline feeding the waterer to prevent freezing. To prevent freezing in the central U.S., most companies recommend at least 10 to 15 animals per waterer space or opening to ensure that the herd drinks two or three volumes of water per day on very cold days, allowing the waterer to refill with warmer water. Placing the waterer in a fence line can allow more livestock to use a waterer.

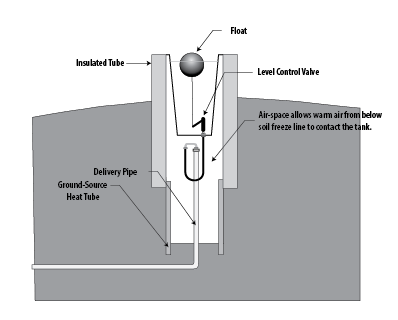

The combined heat from a vertical “earth tube” installed in the ground below the waterer and the above-freezing temperature of an underground water source is generally sufficient to prevent ice from forming inside the waterer. Water sources that are colder than groundwater, such as ponds and streams, increase the chances that the waterer will freeze.

Waterer covers help retain the intrinsic heat of the water and seal out cold air and wind. Typical covers are large balls that float tightly against the inside of the tank opening, or doors that the livestock open to reach the water. Occasionally these doors or balls will freeze shut; a bump or tap by the producer will open the door or dislodge the ball. Livestock learn how to access the water.

Ideally, insulated waterers should be placed in a sunny location protected from wind and snow to minimize heat loss and reduce the chance of freezing. Producers should check the waterer twice a day in cold weather: once in the morning to make sure that livestock can access the water, and again near evening to be sure the float and valve are operating properly.

Most insulated waterers require a solid base such as a concrete pad. Recommended installation includes a hardened surface around the concrete pad.