Concrete Waterer

Overview

Concrete waterers are reliable and durable. They can be installed as part of gravity-flow or pressurized systems. The heavy-use area around the waterer can be protected with a geotextile fabric and gravel surface to reduce erosion and mud. Some models allow two pastures to be watered with one fence-line installation.

Advantages

- Can reduce or eliminate direct stream and pond use by livestock.

- Livestock often prefer to drink from a trough rather than directly from live water.

- Can be used with both non-pressurized (gravity flow) and pressurized water sources.

- Long useful life.

- Can be installed to resist freezing.

- Low operational costs.

- Improves water quality and health of pond when used in conjunction with pond fencing.

- Minimal maintenance requirements.

- Producer can install.

- Multiple concrete waterers can be plumbed into one waterline if enough elevation or water pressure is available.

- Does not require a poured concrete pad.

- Many models to choose from.

Limitations

- Tanks are heavy, weighing between 2,300 and 3,000 pounds each.

- Shipping costs may be high.

- If a pond is the water source, a livestock water pipeline under, through or around the pond dam is required.

Design Considerations

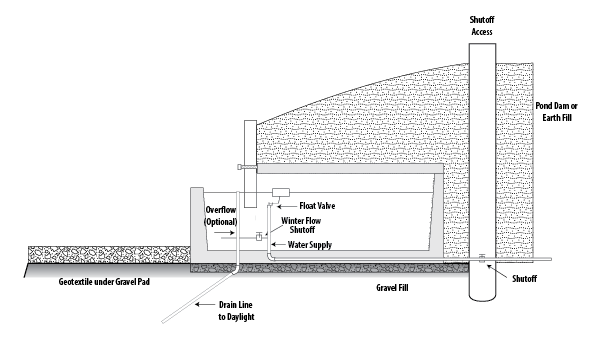

The waterer should be placed on a well-drained gravel or sand site that offers protection from the wind if the waterer will be used during the winter. The site should include a hardened surface area of about 15 feet square in front of the waterer where cattle stand. The pad area can be constructed with geotextile fabric topped with a 6- to 8-inch layer of 1- to 2-inch gravel.

The waterer should be located so that the full water level in the tank is at least 4 feet (preferably 6 feet) below the water level in the pond for adequate gravity flow. The pipeline should be buried below the frost line. After waterer installation, soil is piled around the sides and on top of the rear of the tank baffle to prevent freezing. When possible, the back of the tank behind the exposed water drinking surface should be protected from livestock traffic.

A pond water supply pipeline can be placed either under the dam (new pond construction), or through the dam (existing pond). It is very important to seal the space around the pipeline, especially the area closest to the water edge. The seal can be constructed of compacted clay, an anti-seep collar or bentonite clay.

Installation instructions can be obtained by contacting your watershed specialist or obtaining the K-State Research and Extension publication Alternative Livestock Watering: Covered Concrete Waterer, MF2737, July 2006.