Bottomless Tank Waterer

Overview

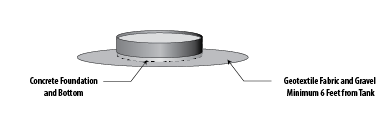

Bottomless tanks are high volume, open-topped tanks used both for storing water and watering livestock. They are often made of corrugated metal sections, such as grain bin sections, bolted together to form a large circular ring on site. A bottom is constructed inside the tank after it is assembled and placed in position. The bottom is usually made of bentonite clay, concrete or plastic membrane.

Because bottomless tanks come unassembled, very large (20 feet or larger diameter) tanks can be assembled. Tanks this size would be prohibitively expensive to ship if they were preassembled. Because of their water storage capacity, these tanks can compensate for the variable water output of windmill and solar panel systems, assuring an adequate supply of livestock water at all times.

The large size of the tanks allows them to be utilized for water storage in gravity fed water systems as well as allowing livestock to drink directly from the tank.

Advantages

- Simple construction.

- Easily adaptable to most sites.

- Large capacity at comparatively low cost compared to other tanks.

- Can be constructed with on-farm labor.

- Serves as both water storage and drinking device.

Limitations

- Tank will eventually need to be rebuilt due to soil-structure properties.

- Livestock may attempt to stand in the tank.

- Difficult to relocate, will require much time, effort and expense.

Design Considerations

Bottomless tanks are generally 25 to 30 inches deep and 20 feet or more in diameter. The lower part of the tank wall is embedded into the tank bottom material.

The tank bottom is susceptible to soil shifting and to changes in soil temperature and moisture. Minor maintenance is required on a regular basis. With substantial effort, tanks can be disassembled, moved, and reassembled at another location.