Wind-powered Systems

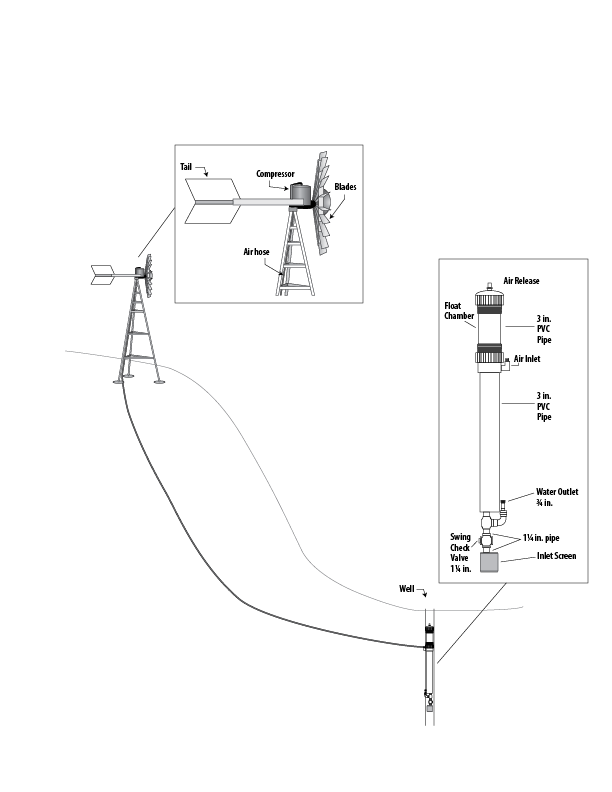

Air lift pumps have low maintenance costs, a long life, and no rotating parts. Compressed air is forced through a small-diameter pipeline that extends below the water line, then the pipeline delivers air through a nozzle into the well water under the lower end of the delivery pipe. An open-ended delivery pipe extends upright from below the water level to a discharge pipe above ground. As the air bubbles move upward, water froth is created and moves up through the delivery pipe. Water is delivered in pulses and the pump is best suited for pumping into an open-topped water tank. Do not use air lift pumps in pressurized water systems. Air lift pumps are relatively inefficient in moving water but can be sited anywhere a wind-powered air pump or other compressed air is available, up to a quarter mile from the delivery point. The pump must be placed deep in the well for it to work. Neither the pump nor any of the pump components are damaged during operation without water.

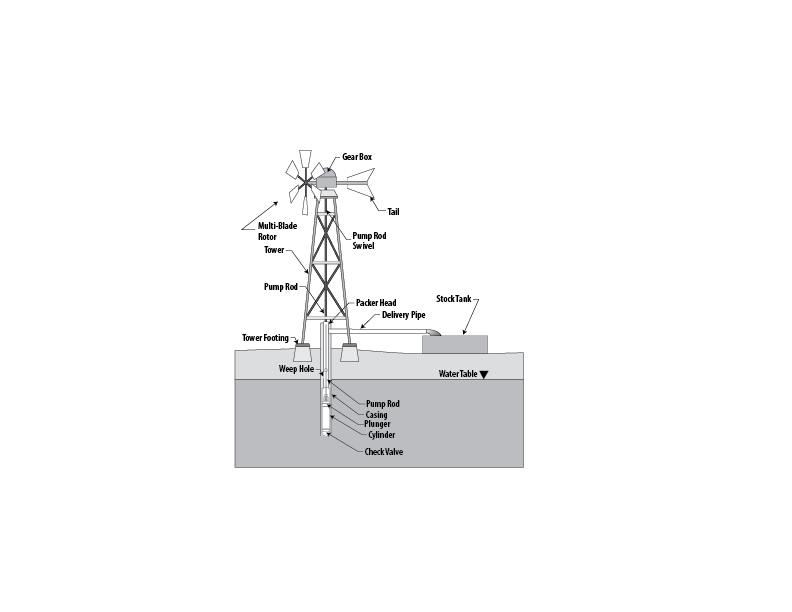

Windmills are comprised of both the windmill head, the tower on which the windmill is supported, and the plunger-type pump driven by the rotation of the windmill head. Windmills are commonly found in grassland areas of Kansas and are suited to remote locations where other power sources are unavailable.

Advantages

- Abundant, free energy source.

- Well-suited to locations where electricity is unavailable.

- Long, useful life.

- Mechanically simple.

Limitations

- Depend on wind blowing, and need large tank or storage tank for when the wind doesn’t blow.

- Maintenance of the windmill head must be done while on top of the tower.

- Contractor may be needed to do maintenance.

- High initial cost.

- Subject to damage in high-wind conditions and severe thunderstorms.

Design Considerations

Windmills should be sited at least 75 feet away from trees or buildings that alter or slow wind currents.

The size of the windmill head should be based on the depth of the well and the size of the pump. Windmill heads range in size from about 6 feet to 20 feet. Larger-size windmill heads are used with deeper wells or a need for higher rate of water delivery. Windmills can lift water 800 feet. The windmill head swivels on the tower to face into the wind using a vane attached to the back side of the head. The head is awkward to handle because of its size and weight.

Windmill heads can be installed on new or reused towers. Towers typically have a metal ladder attached to the side of the tower to facilitate routine maintenance. A windmill brake is used to stop the windmill from turning while being serviced or when water is not needed. Windmill heads should have the gearbox oil level checked twice per year, and oil should be replaced when it becomes dirty. Insufficient or dirty oil will accelerate gear wear. Fan blades should be checked and replaced if necessary.

Pump leathers can last about five years and do not require ascending the tower to be replaced. Sand in the water will decrease the life of the leathers.

Contractors are often hired to handle windmill repair and maintenance services. Consider the contractor’s cost and travel distance when contemplating installing a windmill.

Wind systems: Figure 1

Wind systems: Figure 1

Wind systems: Figure 2

Wind systems: Figure 2