Water-powered Pumping Systems

Overview

Water-powered pumping systems, including sling or ram pumps, require no power other than moving water. An abundant source of water is required for water-powered systems. Water-powered pumping systems are usually considered low cost and have a long life, but they may not be able to deliver adequate flow to provide water to a livestock herd unless multiple units are installed.

Advantages

- Available in a range of sizes for small watering systems.

- Long life.

- No external energy source.

- Low maintenance.

- Well-suited to remote locations with an abundant water source.

- Long delivery lines and high lifts can be achieved under some conditions.

Limitations

- Requires adequate year-round surface water flow.

- Pumps will not work when the moving water freezes.

Design Considerations

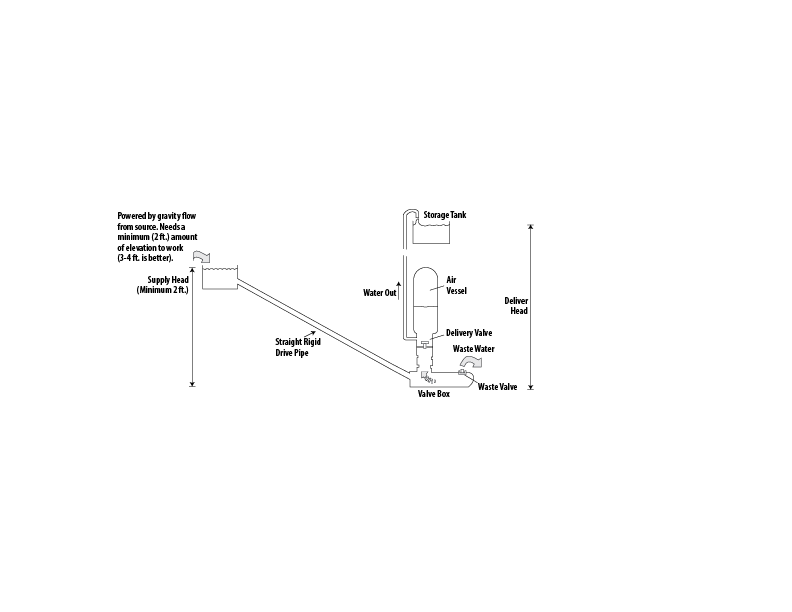

Ram pumps have two check valves, which are the only moving parts of the system. Water flowing through the drive pipe from the stream into the pump picks up speed and drag, which trips the waste check valve closed. The sudden closing of the valve forces water into an air chamber, causing water pressure to build in the chamber as the air is compressed. Ram pumps can be shop-built or purchased commercially.

Water pressure forces open the discharge check valve, and a surge of water passes into the water delivery line before the valve snaps shut from the reduced pressure as the air chamber drains. The waste check valve reopens and the process repeats. The entire process of filling the chamber, pressurizing the water and discharging it can be accomplished in as little as a second. Successive surges of water raise the pressure in the delivery line.

The pump converts the low head, high flow of the water source (stream) to a high head, low flow of a pressurized water delivery. Most of the water flowing through the pump escapes through the waste check valve and flows back into the stream. Only a small proportion is pushed into the water line. The output flow rate depends on the amount of water flowing through the pump and the amount of fall to the pump compared to the lift heights of the delivery water.

The drive pipe is rigid and straight and the length should be about 150 times the pipe diameter. The drive pipe is generally constructed of galvanized steel to withstand the sudden water pressure increase when the waste valve snaps shut.

A standpipe can be installed on the inflow side of the pump to increase the water delivery flow rate by increasing how often the pump cycles, and the water pressure in the delivery line. Standpipes can compensate for a low head or long pipe length. After installing a standpipe, the pipe from the inlet to the standpipe is called the supply line and the pipe from the standpipe to the pump is called the drive line.

The standpipe should be about 1 foot taller than the elevation change between the intake location and the standpipe location. The diameter of the supply pipe above the standpipe is often larger than the standpipe diameter, which in turn has a larger diameter than the drive pipe. The delivery line is often smaller in diameter than the other pipes and is constructed of PVC. Avoid numerous fittings and bends and use a larger diameter pipe to minimize friction losses.

Select sites with at least 2 feet of elevation fall (head) between the water source (intake) and the ram pump. The higher the desired lift, the greater the fall necessary between the water source and the pump. Greater head and stream water flow will increase the delivery flow rate. Streams with steep gradients, waterfalls, or springs perched above streams can provide good sites for ram pump installations. Source water should be free of debris and sand.

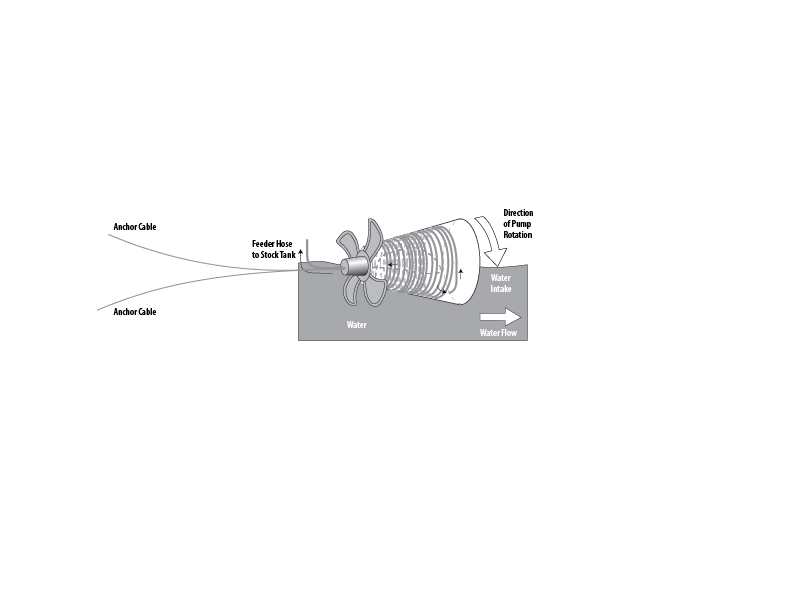

Sling pumps contain many coils of pipe within a cone-shaped housing. A fan is connected to the body of the pump on the upstream side with a center swivel containing the delivery pipe so the pipe does not rotate. The fan is turned by the water flowing in the stream and causes the entire housing to rotate continuously. Water and air enter the coils of pipe as the housing turns. The turning of the housing forces the water counterclockwise through the pump and into the delivery line.

Where the stream is too shallow for the pump, a weir (small dam) can be installed to concentrate the flow and water depth. The pump must be anchored within the stream with stakes and cables, leaving it vulnerable to damage or loss during floods. The pump floats on the water surface, so it can take in both air and water as it turns.

Winter operation of this pump is not practical in Kansas.

References

www1.agric.gov.ab.ca

www.susprep.com/off-grid-water/ram-pumps/

www.youtube.com/watch?v=J2c24Apl4fA

Water-powered systems: Figure 1

Water-powered systems: Figure 1

Water-powered systems: Figure 2

Water-powered systems: Figure 2

Water-powered systems: Figure 3

Water-powered systems: Figure 3