Solar-powered Pumping Systems

Overview

Solar-powered pumping systems provide dependable, low-maintenance watering systems in remote locations and are widely used for livestock watering applications with both well and surface water sources. The cost of a solar pumping system is often less than the cost of bringing an electrical service line to the pump location. Maintenance costs are lower than for windmills. Solar pumping systems are especially useful for temporary water delivery in rotational, crop residue, and cover crop grazing situations.

Advantages

- Compatible with a wide variety of pumps to meet various water pressure and flow rate needs.

- Allows livestock access to drink water away from a stream or pond.

- Long useful life with low operating costs.

- Pump can be replaced by the producer.

Limitations

- Provide intermittent power supply.

- Affected by short winter daylight hours, tree shadows, and cloudy conditions.

- Requires a multimeter to troubleshoot problems.

- Components may not be available at local hardware store, may need to order from specialty supply stores or online.

Design Considerations

Solar pumping systems are powered by sunlight, which is converted to electrical power using photovoltaic panels. Sunshine works well as a power source for livestock watering because the days and times with the greatest solar energy typically coincide with the periods of greatest livestock water demand.

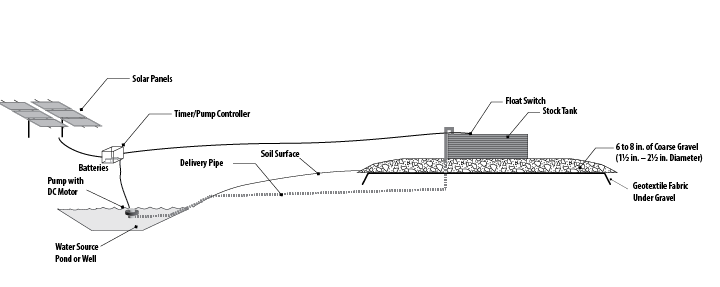

A solar pumping system is comprised of solar panels, a pump (often with a controller), and a storage tank or livestock watering tank. Batteries may be needed to store energy for nighttime or cloudy-weather pumping.

A photovoltaic solar panel converts sunlight to DC electrical power. The size of the panels must match the power requirements of the pump. High lift (deep) wells and higher water pump volumes increase the power requirements (more watt and/or more volts). Solar panels cost about $1 to $2 per watt. Panels have a long life and may have up to a 25-year warranty.

Trackers improve pumping by about 30% to 40% over the course of a summer, possibly allowing a design with fewer panels. For some solar systems, installing additional panels is likely more cost effective than using a tracker. Active trackers powered by electricity being produced by the panels rotate the panels to follow the sun from east to west during the day, increasing power production efficiency. Passive trackers use the sun’s heat to move a liquid from side to side, and gravity moves the panel.

A controller optimizes the variable energy from the solar panel to improve pump performance in low light conditions. Other solar pumping system controls include pump speed, tank water level, low water cutoff (to avoid running the pump when the well is dry), an on/off switch, and indicator lights. Controllers should be sized for voltage and amperage needs of the pump and solar panel.

The pump moves water from the source to the delivery point using the DC power produced by the solar panels. Each additional foot of head the water is lifted requires greater watts of power from the panel. Diaphragm pumps are often used in solar systems with well depths of 100 to 200 feet depending on the water volume delivery requirements. Helical pumps use a screw rotor inside a rubber sleeve to push the water. Helical pumps work well with solar systems, moving water to greater heights or in greater volume than diaphragm pumps. Centrifugal pumps’ pressure (or head) capacity can be increased by stacking additional impellers within the pump.

Cloudy days, nighttime, and other times when the solar panels aren’t producing electricity can be mitigated two ways. A water storage tank or cistern provides several advantages. Storing water, rather than electricity in batteries, is often less expensive and more efficient and reliable. A storage tank should hold a minimum of a three-day water supply. Batteries add cost to the system (as do storage tanks) but batteries can have more maintenance problems.

The combined cost of the solar components as described above would be about $2,500 and would have the capacity to pump 75 feet of head with a flow rate of 3 gallons per minute.

Surface water pumping systems move water from shallow wells, streams, or ponds to livestock watering tanks. Surface water systems are assembled using solar panels, charge controllers, float switches, relays, and pumps and may not require expensive pump control circuitry. Low-cost, portable 12-volt systems often require a battery wired into the system to provide the amperage necessary for the pump. The charge controller prevents the solar panel(s) from excessive battery charging and discharging. The relay allows a high-current pump to be turned on and off by a float or other switch mechanism which can only handle a low amount of current. When greater volume or lift is required, a 24-volt system can be used.

Surface water systems may use diaphragm (ATV sprayer pumps) and centrifugal pumps (12-volt sump pumps). There are a variety of submersible diaphragm, centrifugal and helical pumps available from U.S. and foreign sources online. These pumps are usually reliable but not as well-known as those from more prominent brands.

Solar systems: Figure 1

Solar systems: Figure 1