Considerations for Sizing a Watering System

Water is essential to animal growth. Correctly sizing the watering system ensures the water needs of livestock are met.

Definitions

The water requirement is how much water is needed per day to meet an animal’s nutritional requirement. The daily water requirement is typically measured in terms of gallons per day based on number of animals and animal body weight.

An animal unit (AU) is 1,000 pounds of body weight and is used to calculate stocking rates and water needs. An individual animal’s AU equivalent can be calculated by dividing the weight of the animal by 1,000.

Animal units can be calculated for an entire herd using the following formula:

Total herd animal units = (average weight of an animal in the herd) × (number of animals) ÷ 1,000

Water demand (peak water usage) is based on the maximum amount of water consumed during a 15- or 30-minute interval during the day when each animal in the herd requires an opportunity to drink. Water demand is an estimate of the maximum amount of water needed to rapidly refill a stock tank, trough, or water bowl and is generally measured in gallons per minute (volume per time period). Refill rate becomes increasingly important as herd size increases.

Flow rate is the volume of water that crosses a point in the pipeline during a time period and is measured in gallons per minute (gpm).

Total pressure drop (or head loss) is a sum of the reductions in pressure from the difference in elevation between the water source and the pipe outlet at the delivery point, plus the friction loss due to the velocity of the water moving through the length of pipe, plus the loss of pressure by each coupler, ell, and valve used along the pipeline. Pressure drop is measured in feet of head or pounds per square inch (psi).

Refill rate is the time required for the water in a tank or waterer to be replenished after animals have been drinking. It is measured in gallons per minute.

Drinking space is the linear space of tank access required for one animal to drink from a tank. About 20 inches of space should be allowed for each animal drinking from a circular tank and 30 inches for rectangular tanks. Table 2 offers estimates of the number of water drinking spaces provided by tanks of differing dimensions.

Seven Steps For Sizing a Watering System

Seven steps for sizing a watering system are discussed in the following text. Obtaining expert advice and review is recommended for best results.

Step 1: Determine daily drinking water requirements.

The daily drinking water requirement is a function of the number of animals and body weight. Generally, a minimum of 10 gallons per animal unit of water is required daily during mild and cold weather. During hot weather, water consumption can double to 20 gallons per day per animal unit. Table 1 compares the water requirements based on number of animals and time of year assuming one animal is equal to 1 animal unit. Often, the average body weight is different than 1,000 pounds, and water needs should be adjusted accordingly. The guidelines in Table 1 assume the watering system will supply all water needs of the livestock and does not consider water intake from other sources such as wet forages (silage, distiller grains, or cover crops), forages covered with dew, snow, or rain, or ephemeral water ponds in low spots in pastures.

The water system should be sized to meet 100% of the current daily water demands based on 100% full stocking of the grazing area.

Step 2: Determine water demand (peak water usage).

When water tank capacity or space around a waterer is limited, waterers must refill rapidly to allow the entire herd to drink in a relatively short amount of time. Limited space is defined as when 10% or fewer of the animals in the herd are able to drink from the waterer simultaneously. Animals experiencing a lengthy wait for the tank to refill spend less time grazing, and animal performance will be negatively affected. A dominant animal may limit the access of other cattle to the water tank if the watering point is too small or only has a single watering point.

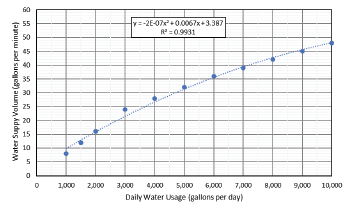

Guidelines for water demand based on daily water usage can be found in Figure 1. For example, if the daily water usage is 2,000 gallons per day, the pumping system should be able to pump approximately 15 gallons per minute. The daily water supply could be met if the pump operated about 2¼ hours per day. As water requirements increase, such as during hot weather or with growing animals increasing in weight, the amount of time the pump will need to run to replenish the watering tank increases.

If a watering system has a continuous water flow of less than 5 gallons per minute, the water trough must have enough storage capacity to allow multiple animals to drink simultaneously and concurrently.

Generally, water demand should be considered adequate if a system pumps 10 gallons per minute or more, with no more than 50 animals in the pasture.

Storage capacity can be achieved by increasing the size of the tank (in-tank storage) or by adding a storage reservoir between the water source and the tank. If the decision has been made to install a storage tank or other additional storage capacity, there are three basic options.2

Option 1 – install a water storage tank regardless of continuous flow rate.

Option 2 – if continuous flow rate is less than 5 gallons per minute, water storage tanks should be installed to allow multiple animals to simultaneously drink during periods of peak demand.

If the continuous flow rate is 5 gallons per minute or higher and there is no storage tank, the required continuous flow (refill rate) should equal 1 to 2 gallons per minute per drinking space.

Water tanks that can hold an entire day’s requirement of water for the herd need a minimum flow rate equal to the daily water requirement ÷ 1,440 minutes per day.2 When the flow rate exceeds water requirements and there is no shutoff valve, an overflow pipe should be installed to prevent water from spilling over the tank edge and accumulating around the base of waterer.

Step 3. Determine the number of drinking spaces needed.

At least 10% of the animals in a pasture or pen should be able to drink simultaneously.2 About 20 inches of space should be allowed for each animal drinking from a circular tank and 30 inches for rectangular tanks.2 Generally a minimum of two water points is necessary to prevent the dominant animal in the herd from standing at or in the water point during periods of heat stress or hot weather and restricting access by other animals.

Water tanks can be installed along a fence or structure that restricts access to only one side of the tank and will provide only half the number of drinking spaces. When cattle are drinking from both sides of a tank, the tank width should be a minimum of 30 inches.

See Tables 2a and 2b for estimates of the number of water spaces provided by tanks of differing dimensions.

Follow the manufacturer’s drinking space recommendations for cup, bowl, or small tub waterers. If recommendations are not available, provide one drinking space per 20 animals.2 This assumes water is available in each bowl, and livestock drink one at a time.

Water intake by beef cattle occurs during an 8- to 10-minute period each day. If water is readily available, cattle will visit the watering point six to 10 times per day. Cattle consume water at an average rate of 6 gallons per minute, but consumption rate can vary between 2 to 12 gallons per minute. While cattle may be able to consume their daily water supply in a relatively short time during each visit, they also need time to move to and from an open water space as it becomes available.

Cattle may consume their entire daily water intake in one visit to a water source if they must travel a long distance to water, resulting in increased drinking time per animal and requiring enough drinking spaces for 15% to 20% of the herd to drink simultaneously. Consider providing additional drinking spaces and faster refill rates when pastures are large, distances to water are long, waterer storage capacity is low, or herd size is large.

Step 4. Determine storage volume requirements.

If a storage reservoir cannot be refilled in one hour, then a storage reservoir should be sized large enough to store all the water that will be needed by the herd for one day. Wind or solar powered watering systems need a storage reservoir that holds enough water for two to three days (stock tank volume + storage tank volume).

Table 3 shows the volume of water available in a round storage tank based on diameter and water depth. The diameter will determine how many drinking spaces are available. The tank depth and diameter determine how much water the tank will store. For example, if a tank is 12 feet in diameter and water depth is 12 inches, then the tank will hold 846 gallons. The reservoir capacity is based on the depth of water the cattle can easily reach rather than the full depth of water held in the tank: Even if the tank is 20 inches high, cattle may only be able to reach the top 15 inches of water.

Step 5. Determine available water output.

Table 4 provides estimates of the water output for several types of watering systems. Seepages and springs may have continuous flow but at a slow rate of discharge. If livestock are consuming 6 gallons per animal per drinking event and the flow rate is 1 gallon per minute, it will take 6 minutes of refill time before the next animal can drink unless there is water storage available either in the tank or from a storage reservoir.

Step 6. Determine pipe diameter.

Pipe size requirements are determined by the water demand or peak water flow rate and head pressure available. Peak demand for a seepage or spring system generally equals the continuous flow rate. Flow rates for several pipe diameters are shown in Table 5 when water velocity is 4.5 feet per second or less.

When water velocity is greater than 4.5 feet per second, pipe friction loss must be considered when calculating the required head pressure. Pipe friction can be decreased by selecting a larger diameter pipe.

It is better to oversize rather than undersize the watering system to avoid limiting potential herd growth due to a lack of adequate water delivery. By using a slightly larger pipe size than the design size, the watering system can accommodate future herd growth by having the capacity to supply additional water troughs or tanks.

The most common pipe type in livestock watering systems is PVC pipe. Tables 5 and 6 is based on PVC pipe and must be adjusted if using other piping material. The pressure drop due to water velocity is generally assumed to be negligible if the water velocity is less than 5 feet per second (fps) through the pipe. The water velocity in Tables 8 and 9 is assumed to be 4 feet per second to minimize the affect of water velocity. The total pressure drops in Tables 5 and 6 are the difference between the difference in elevation between the pipe inlet at the water source and the pipe outlet at the delivery point. The total pressure drops increase as the pipeline length and inside roughness of the pipe increase (head loss).

Step 7. Impact on head pressure.

When water is moved through the pipeline, from the water source to the waterer, the distance the water can be moved is determined by the pipe material, diameter of the pipe, the volume (gpm) and head pressure (psi). Friction loss of the pipe is determined by the velocity of the water in the pipe, (feet per second), and roughness coefficient of the pipe. Each elbow, valve, coupler or any other joints or insertions along the pipeline create turbulence and add to friction loss. Friction loss is measured as pressure drop for each 100 feet of pipeline plus the loss for each additional pipe fitting.

Table 6 shows the distance water can be transferred as a function of nominal pipe diameter (inches), head pressure (psi), and water flow rate (gpm) for PVC pipe. Other pipe materials such as steel or copper will have different transfer distances.

Summary

These seven steps provide basic guidelines for sizing a watering system. Local experts can provide additional insight to ensure livestock water needs are met.

Example of a Water System Design

A pasture can support 30 cattle weighing 750 pounds during the summer months. The watering system is a solar pump system pumping 5 gallons per minute. The distance from the water source to the round water tank is 200 feet and vertical head pressure is 10 feet.

Determine the tank diameter and recommended pipe diameter.

Design Considerations

Step 1: Convert to animal units (A.U.).

30 head × 750 pounds/head/1,000 pounds = 22.5 animal units

Step 2: Determine daily water requirements for summer months.

22.5 A.U. × 20 gallons per day per A.U. = 450 gallons per day

Step 3: Determine minimum number of water spaces.

30 head × 10 % minimum water spaces = 3 head

Or

30 head × 20% minimum water spaces = 6 head (if the cattle are in a large enough pasture that they only drink water one time per day)

Step 4: Determine round tank diameter.

Using Table 2, one 4-foot diameter tank will provide drinking space for 8 head. A 4-foot diameter tank has a water volume of 141 gallons in 18 inches of depth. A 6-foot-diameter tank has the capacity for 211 gallons in 12 inches of water depth.

The three-day storage recommendation for solar powered water systems would require 1,350-gallon total (450 gallons per day × 3 days). The options are one 16-foot-diameter stock tank or one 4-foot stock tank with a 1,250-gallon storage tank gravity flowing to the stock tank.

Step 5: Determine the water demand (gallons per minute).

Using Figure 1 and based on daily water requirements of 450 gallons per day, the minimum water demand is approximately 5 gallons per minute. If the eight head were to drink 2 gallons per head per minute, the demand rate would be 16 gallons per minute.

Step 6: Determine pipe diameter.

Two options for stock tank sizes were determined in Step 4, the 16-foot stock tank that can hold the three-day recommended storage of 1,350 gallons or a 4-foot stock tank that will hold 141 gallons with a 1,250-gallon storage tank above it that will gravity flow water into the stock tank.

Option 1, using the 16-foot stock tank:

Use Table 5 to find that a 1-inch pipeline can carry the 5 gallons per minute flow from the pump. Table 3 confirms that the 1-inch pipeline with 20 to 30 psi can move water further than the proposed 200 feet. Therefore, select a 1-inch PVC pipe to convey the water from the pump to the stock tank.

Option 2, using the 4-foot diameter stock tank with the 1,250-gallon storage:

Use Table 5 to find that a 1-inch pipeline can carry the 5 gallons per minute flow from the pump. Table 3 confirms that the 1-inch pipeline with 20 to 30 psi can move water further than the proposed 200 feet. Therefore, select a 1-inch PVC pipe to convey the water from the pump to the storage tank.

The flow rate for filling the stock tank must be 16 gallons per minute so the livestock can drink in a timely manner. In Table 6, in the Gravity-Flow Systems section, looking at the 20-gallons-per-minute column, when the tank is full (10 foot head), a 1-inch line would work to deliver the water 10 feet or less. But when the tank is less than half full, as may occur during cloudy weather since this is a solar-powered system, the water in the lower half of the tank will have less than 5 foot of head pressure, so a larger pipe diameter is required. While technically a 1½-inch pipe could serve as the gravity-flow delivery pipe, assuming the distance is short, a more dependable solution would be to use a 1-inch pipe to carry the water from the pump to the storage tank and a 2-inch pipe to serve as the gravity-flow water source to the smaller stock tank.

References

Brown, L. 2006. Livestock water system design #1. Selecting flow rate, pressure, trough size and storage. Ed. BC Livestock Watering Handbook, 1990: 2-4, BC Ministry of Agriculture and Fisheries. B.C. Livestock Watering Handbook - Province of British Columbia (gov.bc.ca)

Marsh, L. 2001. Pumping water from remote locations for livestock watering. Publication 442-755. Virginia Cooperative Extension. Virginia Tech. Blacksburg, VA.

Table 1: Daily water requirements (gallons/day/animal unit) based on number of animals vs. cold or hot weather.

| Number of Animals* | Daily Cold Weather Water Reqirements | Daily Hot Weather Water Requirements |

|

1 |

10 | 20 |

| 25 | 250 | 500 |

| 50 | 500 | 1,000 |

| 75 | 750 | 1,500 |

| 100 | 1,000 | 2,000 |

| 125 | 1,250 | 2,500 |

| 150 | 1,500 | 3,000 |

| 175 | 1,750 | 3,500 |

| 200 | 2,000 | 400 |

| 225 | 2,250 | 4,500 |

| 250 | 2,500 | 5,000 |

| 275 | 2,750 | 5,500 |

| 300 | 3,000 | 6,000 |

*One animal unit is assumed to weigh 1,000 lbs

Figure 1: Adaption from Brown (2006) of recommended peak water demand (gallons per minute) based on daily water usage (gallons per day).

Figure 1: Adaption from Brown (2006) of recommended peak water demand (gallons per minute) based on daily water usage (gallons per day).

Table 2a (Water tank - Round): Number of water drinking spaces required for water tanks based on tank diameter (ft) and water troughs with straight sides based on trough length (ft).

| Tank diameter (feet) | Water Drinking Spaces* | Recommended Animals Per Tank ** |

| 4 | 8 | 80 |

| 6 | 12 | 120 |

| 8 | 16 | 160 |

| 10 | 19 | 190 |

| 12 | 23 | 230 |

| 16 | 31 | 310 |

*Assumes 20 inches of drinking space per animal

**Assumes water space available for 10% of animals

Table 2b (Water Trough - Straight Sides): Number of water drinking spaces required for water tanks based on tank diameter (ft) and water troughs with straight sides based on trough length (ft).

| Trough length (feet) | Water Drinking Spaces/Side* | Recommended Animals Per Trough Side ** |

| 6 | 2 | 20 |

| 8 | 3 | 30 |

| 12 | 4 | 40 |

| 16 | 6 | 60 |

| 20 | 8 | 80 |

| 24 | 9 | 90 |

*Assumes 30 inches of drinking space per animal

**Assumes water space available for 10% of animals

Table 3: The storage volume (gallons) of different size round tanks (feet) vs. storage depth of water (inches) available for drinking.

| Tank Diameter (feet) | 9 inches (depth) | 12 inches | 15 inches | 18 inches | 24 inches |

| 4 | 70 gallons | 94 gallons | 117 gallons | 141 gallons | 188 gallons |

| 6 | 159 | 211 | 264 | 317 | 423 |

| 8 | 282 | 376 | 470 | 564 | 752 |

| 10 | 441 | 587 | 734 | 881 | 1,175 |

| 12 | 634 | 846 | 1,057 | 1,269 | 1,692 |

| 16 | 1,128 | 1,504 | 1,880 | 2,256 | 3,008 |

Table 4: Difference in daily water available for typical watering systems and number of animal units that may be watered during cold/mild and hot weather.

| Type of Water Supply System | Load Size (gal/load) or Pump Volume (gpm) | Loads or Pumping Time/Day | Available Water per Day (gal) | Cold Weather Water Consumption 10(gal/AU/day)* | Mild Weather Water Consumption 20(gal/AU/day)* |

| Haul | 300 loads | 2 loads/day | 600 | 60 | 30 |

| Seepage | 0.5 pump | 24 hours/day | 720 | 72 |

36 |

| Spring | 1 pump | 24 hours/day | 1,440 | 144 | 72 |

| Wind/Solar | 2 pump | 6 hours/day | 720 | 72 | 36 |

| Wind/Solar | 4 pump | 6 hours/day | 1,440 | 144 | 72 |

| Gravity Flow | 5 pump | 12 hours/day | 3,600 | 360 | 180 |

| Well or Rural Water | 10 pump | 8 hours/day | 4,800 | 480 | 240 |

| Well or Rural Water | 15 pump | 8 hours/day | 7,200 | 720 | 360 |

*Maximum Animal Units (AUs) based on water available. An animal unit is assumed to equal 1,000 lbs of live weight. Water available assume 100% of water consumption is supplied by watering system.

Table 5: Recommended minimum pipe diameter based on water flow rate (gpm).

| Pipe Diameter (inches) | 5* | 10* | 15* | 20* | 25* | 30* |

| 1 | OK | — | — | — | — | — |

| 1.5 | OK | OK | OK | — | — | — |

| 2 | OK | OK | OK | OK | OK | — |

| 2.5 | OK | OK | OK | OK | OK | OK |

| 3 | OK | OK | OK | OK | OK | OK |

*Water Flow Rate (gallons/minute)

** OK indicates pipe diameter is OK to use with given water flow rate (gpm) since the water flow rate is less than 4.5 fps. No value indicates pipe diameter is not recommended at given water flow rate.

Table 6: Distance Water Can be transferred based on water flow rate (gal/min) and head pressure drop (feet or head or psi)

Gravity-flow Systems (2.2 PSI – or 5 ft. head)

| Pipe Diameter (in) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) |

| 5 | 10 | 15 | 20 | 25 | 30 | |

| 1 | 120 | 40 | 20 | 10 | 10 | 10 |

| 1.5 | 950 | 270 | 130 | 80 | 50 | 40 |

| 2 | 3,240 | 900 | 430 | 250 | 170 | 120 |

| 2.5 | 2,130 | 1,010 | 600 | 400 | 280 | |

| 3 | 2,920 | 1,720 | 1,140 | 810 |

Low-Pressure Systems 20 PSI (e.g., 20-40 pressure switch or 70 ft. head)

| Pipe Diameter (in) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) |

| 5 | 10 | 15 | 20 | 25 | 30 | |

| 1 | 1,590 | 450 | 210 | 130 | 90 | 60 |

| 1.5 | 3,670 | 1,740 | 1,020 | 680 | 490 | |

| 2 | 3,480 | 2,970 | 2,120 | |||

| 2.5 | ||||||

| 3 |

Medium-pressure Systems 40 PSI (e.g., 40-60 pressure switch or 100 ft. head)

| Pipe Diameter (in) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) |

| 5 | 10 | 15 | 20 | 25 | 30 | |

| 1 | 2,050 | 570 | 270 | 160 | 110 | 80 |

| 1.5 | 4,720 | 2,230 | 1,310 | 870 | 620 | |

| 2 | 4,480 | 2,970 | 2,120 | |||

| 2.5 | ||||||

| 3 |

High-pressure Systems 60 psi (e.g., 60-80 pressure switch or 140 ft. head)

| Pipe Diameter (in) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) |

| 5 | 10 | 15 | 20 | 25 | 30 | |

| 1 | 1,370 | 380 | 180 | 110 | 70 | 50 |

| 1.5 | 3,150 | 1,490 | 880 | 580 | 420 | |

| 2 | 5,090 | 2,990 | 1,980 | 1,410 | ||

| 2.5 | 4,700 | 3,350 | ||||

| 3 |

Very-high-pressure systems 80 PSI or greater (or 185 ft. head)

| Pipe Diameter (in) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) | Flow rate (gpm) |

| 5 | 10 | 15 | 20 | 25 | 30 | |

| 1 | 4,200 | 1,170 | 550 | 330 | 220 | 160 |

| 1.5 | 4,580 | 2,690 | 1,780 | 1,270 | ||

| 2 | 4,350 | |||||

| 2.5 | ||||||

| 3 |