Pipeline Network for Multiple Waterers

Overview

When several waterers are located relatively close to each other, a pipeline network may be less expensive than installing a separate pump, energy source, and direct pipeline to the water source for each waterer. Pipeline diameter is contingent on the combined length of the pipelines, differences in elevation, and combined water demand of all the waterers. A pipeline network design is specific to the site, the herd water requirements, and pasture arrangement.

Advantages

- A single water source, pump, energy supply, and storage tank can supply multiple waterers.

- May be less expensive and more reliable than developing a separate watering system for each waterer.

- Multiple water sources can be combined to deliver water to many waterers.

- Suited when power supply is limited to a single location, but water delivery is needed for multiple waterers.

Limitations

- Backup pumps and power sources are more important because a single failure impacts multiple waterers.

- Water source must have an adequate flow rate to supply all the waterers.

- Shallow rock layers can impede laying pipeline.

- Design must be specific to the site.

- May require a contractor to design and install.

Design Considerations

The assistance of a qualified engineer is usually required to determine pipeline sizes and valve locations to ensure adequate system capacity. The system may include air relief valves, vacuum relief valves, shutoff valves, water storage, and thrust blocking as well as pipeline and fittings.

Air relief valves release air that accumulates at high elevation points in the system so it does not restrict water flow.

Vacuum relief valves prevent a vacuum from developing in the waterline on sites with large differences in elevation. A vacuum in the line can cause the pipeline to collapse or break. The vacuum relief valve is often combined with the air relief valve to minimize the number of fittings and reduce cost.

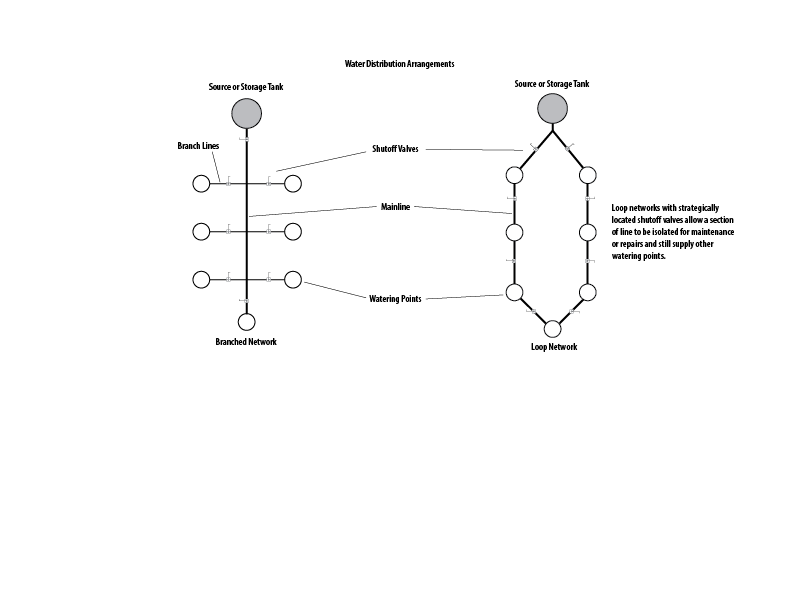

Shutoff valves are installed to allow sections of the pipeline to be isolated for maintenance and repairs. A pipeline network laid out in a loop configuration allows most of the network to remain functional while one section is being repaired. Valves should be installed for each waterer to allow repair and maintenance while the remainder of the waterers remain functional.

Elevated storage tanks use gravity flow to move water rapidly though the network to refill multiple waterers. Large diameter tanks with sufficient head of water within the tank also can provide gravity flow to additional waterers.

Pipeline specifications are tailored to the needs of each section of the network. Pressure losses resulting from pipeline length and pipe diameter, operating pressure, pressure surges, and the strength of the pipe must be considered. Pipe with walls heavier than specified can provide increased durability, years of service, and reduced repair costs. Fittings at least as strong as the pipe should be used. Do not use schedule 40 fittings on schedule 80 pipelines.

Network: Figure 1

Network: Figure 1